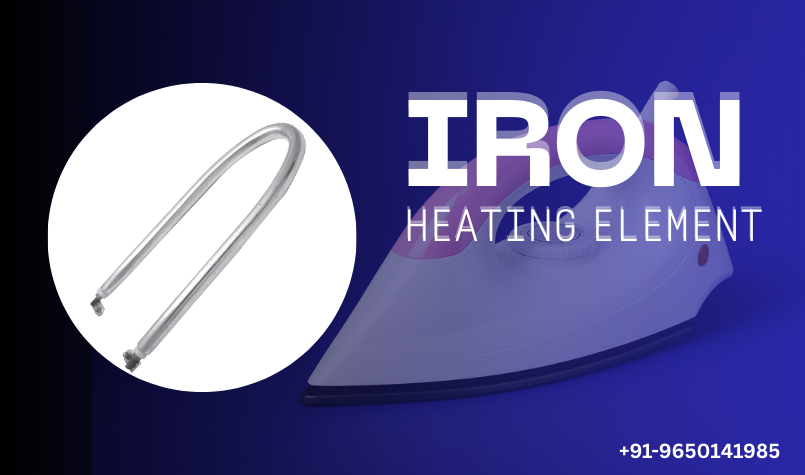

When it comes to ironing clothes, ironing machines, or small iron appliances, one thing many people take for granted is the iron heating element inside it. It’s the core component that transforms electrical energy into heat—without which ironing simply wouldn’t happen. In this blog, we’ll dive into what an iron heating element is, the types and materials commonly used, how they work, and what you should know when choosing or replacing one.

Put simply, an iron heating element is the part of an electric iron (or similar appliance) that gets hot when electricity passes through it. It is responsible for heating the soleplate (the flat part of an iron) so that wrinkles, creases, or dampness in fabrics can be smoothed out. The element must reliably reach and maintain the correct temperature without burning out or degrading too quickly.

At the heart of the heating element is a material with electrical resistance. When current flows through this resistant material, electrical energy is converted into thermal energy (heat). Key factors in how it works:

The design of heating elements in irons or iron machines may vary, depending on cost, durability, and intended use (household / industrial). Here are some common types and their characteristics:

|

Type |

Description |

Pros |

Cons |

|

Coiled wire element |

A resistance wire (often nichrome) wound into a coil, embedded in insulating material. |

Simple, cost-effective, easy to manufacture. |

Less uniform heating; potential hotspots; wire degradation over time. |

|

Strip/Plate element |

A flat or finned metal strip or plate where heating resistance may be incorporated. |

More even temperature distribution; faster heat transfer; slimmer design possible. |

More complex manufacturing; costlier; sometimes less flexible. |

|

Ceramic or metal-foil with embedded resistive film |

A heating film embedded in or bonded to ceramic/metal base. |

Very even heat spread; safer surface temperature control; lightweight. |

Usually more expensive; may be more delicate; may require precise control electronics. |

The choice of material affects performance, lifespan, and cost. Some of the widely used materials:

To get the best performance and longevity from your iron, look for:

PowerPack Electricals offers a range of W13 – Light Weight Iron Elements under its heating elements category. These are designed to balance the need for efficient heating with ease of handling and faster heating times because of their lighter mass. Some features you might expect in such products:

If you’re considering replacing or purchasing W13 light weight elements, check whether the element’s material (nichrome, copper, etc.), wattage/resistance rating, and compatibility with your iron model match your needs.

Here are tips for deciding and caring for your iron heating element:

The iron heating element is vital for ironing performance. Whether it's a coiled wire, strip, or embedded film, the materials and design determine how fast it heats, how evenly, how long it lasts—and ultimately, how satisfied you are. For high quality, reliable operation, it’s worth investing in elements like PowerPack’s W13 Light Weight Iron Elements that are made with good materials, proper design, and safety in mind.